Teflon-lined level gauge

Teflon-lined level gauge

Product descriptionUHZ-801F steel lined PTFE non-blind zone magnetic flap (column) liquid level gauge series product

Product Details

Product description

UHZ-801F steel lined PTFE non-blind zone magnetic flap (column) liquid level gauge series products can achieve high sealing, anti-leakage and safe and reliable measurement of liquid level under high temperature, high pressure, high viscosity and strong corrosive conditions, the whole process The measurement has no blind area, eye-catching display, intuitive reading, and large measurement range. Equipped with liquid level alarm and control switch, it can realize the upper and lower limit alarms of liquid level or boundary level. The bit and boundary signals are converted into two-wire 4~20mA, 24V.DC standard signals to realize long-distance detection, indication, recording and control. The series of products are widely used in petroleum, chemical, electric power, medicine, environmental protection, metallurgy, water treatment and other industries.

Scope of application

It is suitable for the measurement of corrosive liquids such as hydrochloric acid, nitric acid, sulfuric acid, etc.

Structural Principles

UHZ-801F steel-lined PTFE non-blind zone magnetic flap (column) level gauge According to the buoyancy principle and the working principle of magnetic coupling, when the liquid level in the measured container rises and falls, the float in the main pipe of the level gauge also rises and falls. The permanent magnet steel in the float is transmitted to the on-site indicator through magnetic coupling, and drives the red and white flip columns or flaps to turn 180°. When the liquid level rises, the magnetic flip columns or flaps turn from white to red, and when the liquid level drops When the turning column or turning plate changes from red to white, red indicates liquid phase, white indicates gas phase, and the red and white boundary of the indicator is the actual height of the medium liquid level in the container, so as to realize the liquid level indication.

Basic parameters

Measurement range L: 300~10000mm

Measurement accuracy: ±5mm

Working temperature: -20℃-180℃

Working pressure: 0.6-2.5MPa

Media density: 0.8-2.0 g/cm3

Flange: DN15 DN20 DN25 RF

Flange standard: HG20592--20635-2009

Other flange standard please specify

Material: Bypass pipe: 304+PTFE F46 Float: 304+PTFE F46

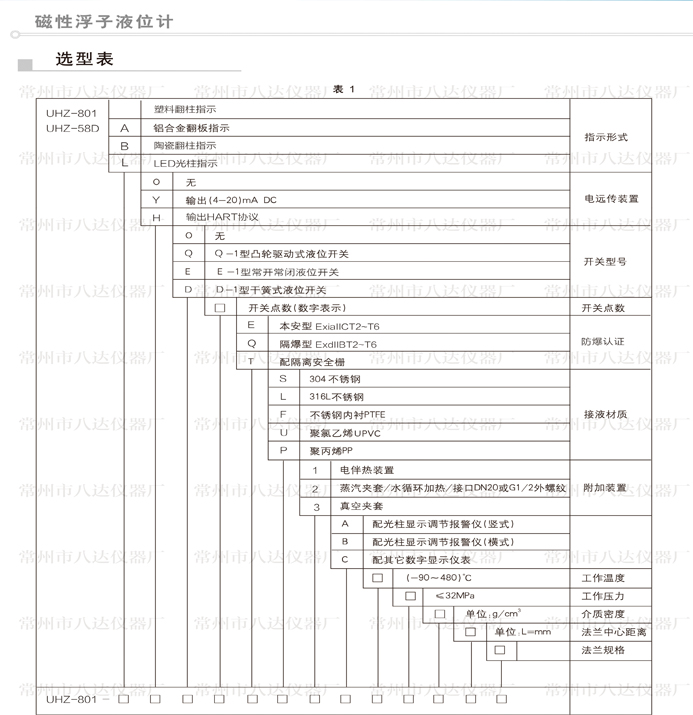

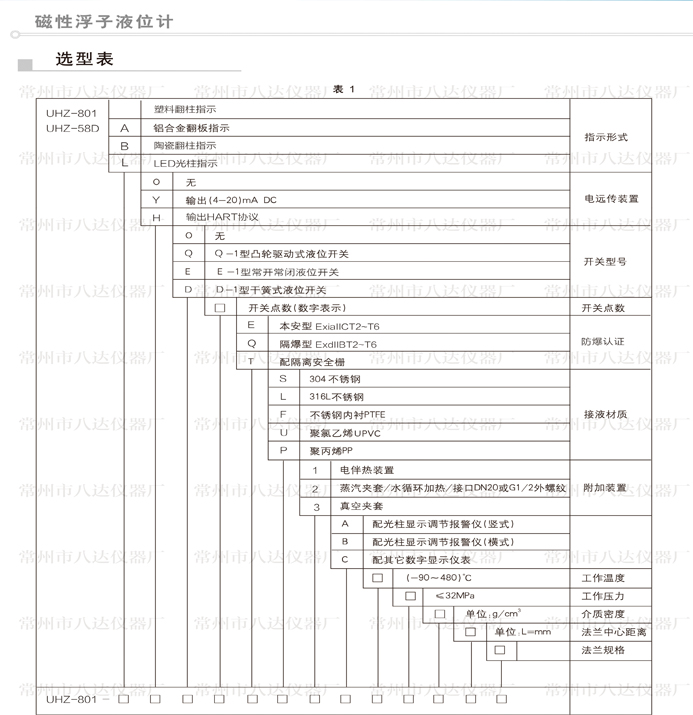

For detailed configuration, please refer to the selection table

Measurement accuracy: ±5mm

Working temperature: -20℃-180℃

Working pressure: 0.6-2.5MPa

Media density: 0.8-2.0 g/cm3

Flange: DN15 DN20 DN25 RF

Flange standard: HG20592--20635-2009

Other flange standard please specify

Material: Bypass pipe: 304+PTFE F46 Float: 304+PTFE F46

For detailed configuration, please refer to the selection table

Install and use

1. First, check whether the data on the liquid level gauge is in line with the order requirements. There must be no magnets and other magnetic substances within 200mm around the liquid level gauge, otherwise it will affect the normal operation of the liquid level gauge.

2. A shut-off valve should be installed between the liquid level gauge and the container, so as to cut off the material during maintenance and cleaning. The installation of the body must be vertical, and the maximum deflection angle is ≤3°. When the measurement range is greater than 4m, the intermediate support point should be added during installation and use.

3. Before the liquid level gauge enters into operation, the upper flange gas phase valve should be opened first, and then the lower flange liquid phase valve should be opened slowly, so that the medium slowly flows into the cylinder, so that the magnetic flip column can track the instructions one by one, and use the adjusting screw Adjust the zero level.

2. A shut-off valve should be installed between the liquid level gauge and the container, so as to cut off the material during maintenance and cleaning. The installation of the body must be vertical, and the maximum deflection angle is ≤3°. When the measurement range is greater than 4m, the intermediate support point should be added during installation and use.

3. Before the liquid level gauge enters into operation, the upper flange gas phase valve should be opened first, and then the lower flange liquid phase valve should be opened slowly, so that the medium slowly flows into the cylinder, so that the magnetic flip column can track the instructions one by one, and use the adjusting screw Adjust the zero level.