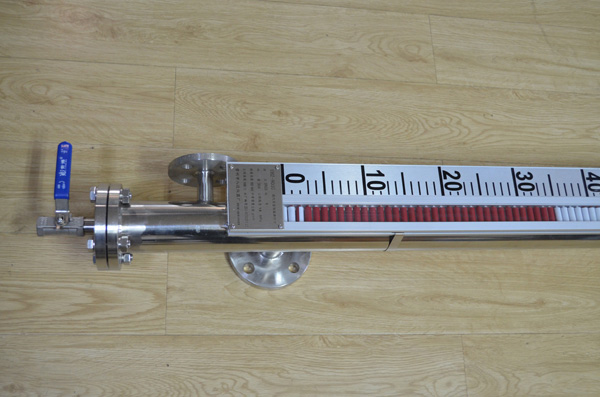

As a field indicating liquid level instrument, the magnetic flap liquid level gauge is widely used in liquid level measurement in all walks of life and is very popular. The reason for this is determined by the types and characteristics of the magnetic flap level gauge. This article will introduce the types and characteristics of the magnetic flap level gauge, and hope to help you better understand the magnetic flap level gauge. for detailed understanding.

1. Types of magnetic flap level gauges

According to different standards, the magnetic flap level gauge can be divided into different categories, such as according to the degree of corrosion of the liquid to be measured, divided into non-corrosion type, low corrosion type and high corrosion resistance type magnetic flap level gauge. According to the pressure level, it can be divided into low pressure, central Asia and high pressure type magnetic flap level gauge and so on. In order to adapt to the chemical properties of different media, and also to meet the different needs of different users, to provide users with more cost-effective products, Flap-11 series magnetic flip level gauges have the following four categories: Flap-11A standard magnetic flip Plate level gauge, Flap-11C plastic type magnetic flap level gauge, Flap-11S economical type magnetic flap level gauge, Flap-11P lined PTFE anti-corrosion type magnetic flap level gauge.

2, the advantages of the magnetic flap level gauge

Compared with other liquid level gauges, the advantages of the magnetic flap level gauge are obvious. In general, the characteristics and advantages of the magnetic flap level gauge are as follows.

1. The most prominent advantage of the magnetic flap liquid level gauge is its function of displaying the liquid level height in real time. Not only that, the reading is also very intuitive and accurate, which undoubtedly brings great convenience to on-site operations;

2. The magnetic flap level gauge has strong sealing degree and protection ability, and can work safely and reliably even in various harsh environments such as low temperature, high temperature, high pressure, and strong corrosion. It is especially suitable for liquid level measurement in outdoor tanks, storage tanks and boilers. The protection level of the Flap-11 series magnetic flap level gauge reaches the highest standard in the instrument - IP66/67, with good sealing performance and high reliability.

3. The magnetic flap level gauge uses the magnetic float as the sensing element, and uses the magnetic steel to drive the flap indication, so there is no need for energy assistance. In addition, the magnetic flap level gauge has high compatibility and is widely used in industrial production. It is an ideal choice for liquid level measurement in tanks, tanks and other containers.

In addition to the above-mentioned more common advantages, the four types of magnetic flap level gauges also have different characteristics and advantages, which are as follows:

1. Flap-11A standard magnetic flap liquid level gauge, suitable for liquid level measurement of most weak corrosive liquids

The Flap-11A standard magnetic flap level gauge made of 316L stainless steel is suitable for most weakly corrosive liquid level measurements. Among them, the buoy is made of high-quality seamless steel pipes with a diameter of 51mm × 2 to prevent liquid leakage and bring important guarantees for high-efficiency production operations.

2. Flap-11C plastic type magnetic flap liquid level gauge, suitable for liquid level measurement of low pressure and strong corrosive liquids

The plastic type magnetic flap level gauge is a commonly used anti-corrosion type level gauge. Under the same range, the weight is only about 1/5 of the standard type magnetic flap level gauge. The buoy is made of φ50×4.2 PP pipe, which is very suitable for chemical water treatment in power plants, sewage treatment, printing and dyeing industries, and other acidic media that are incompatible with PP.

3. Flap-11S economical magnetic flap level gauge, suitable for liquid level measurement of most working conditions and slightly corrosive liquids

Using 304 stainless steel as raw material, it is suitable for liquid level measurement of slightly corrosive liquids such as tap water and oily media in most common working conditions. The buoy is made of high-quality 304 seamless stainless steel pipe with a diameter of 51mm × 2, and a product welded pipe with a diameter of 51mm × 1.5 can also be selected for use in non-corrosive media systems at room temperature and pressure.

4. Flap-11P lined with PTFE anti-corrosion magnetic flap level gauge, suitable for level measurement of strong corrosive liquids

Flap-11P float is lined with 304 PTFE, which is mainly used for the measurement of strong corrosive liquids such as strong acid, strong alkali, strong oxidant, organic solvent, etc., and is widely used in chemical industry, oil refining, storage and transportation, water treatment and other industries.

Note: The article is from the Internet, if there is any infringement, please contact me to delete it!