Metal tube rotameter

Metal tube rotameter

Product DescriptionMetal tube rotameter (metal tube rotameter) is a variable area flow measurement instrument common

Product Details

Product Description

Metal tube rotameter (metal tube rotameter) is a variable area flow measurement instrument commonly used in industrial automation process control. It has the characteristics of small size, large detection range and convenient use. It can be used to measure the flow of liquid, gas and steam, and is especially suitable for the measurement of low flow rate and small flow.

Over the years, the metal tube rotameter has been widely used in petrochemical, steel, electric power, metallurgy, light industry, food, pharmaceutical, water treatment and other industries due to its excellent performance and reliability, as well as a good performance-price ratio. Wide range of applications.

Over the years, the metal tube rotameter has been widely used in petrochemical, steel, electric power, metallurgy, light industry, food, pharmaceutical, water treatment and other industries due to its excellent performance and reliability, as well as a good performance-price ratio. Wide range of applications.

Structural Principles

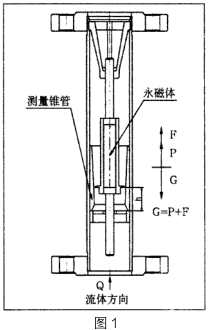

Metal tube rotameter mainly consists of two parts: sensor and indicator. The sensor is mainly composed of connecting flange, measuring cone, float and upper and lower guides; the indicator is mainly composed of shell, magnetic transmission system, dial and electric remote transmission system.

In the vertical conical measuring tube, there is a measuring part that can move up and down - the float (Figure 1). Move up. When the fluid flow increases, the displacement of the float increases; on the contrary, when the fluid flow decreases, the displacement of the float decreases. That is to say, the size of the fluid flow determines the position of the float in the measuring tube, thereby determining the size of the annular area between the float and the conical tube. When the flow rate of the fluid is maintained at a constant flow rate Q, the float is also in a state of dynamic equilibrium and stays at a position h in the conical tube. At this time, the annular area between the float and the conical tube remains constant. The float is acted on by three forces: the gravity G of the float, the buoyancy F received by the float, and the force P of the fluid on the float, and these three forces are in equilibrium. According to the Bernin equation of fluid dynamics, the principle of force balance and the law of fluid continuity, the instantaneous fluid flow through the annular area can be calculated at this time. Therefore, the metal tube rotameter uses a variable area to measure the flow. principle.

Inside the float, a high-performance permanent magnet is embedded. When the float is in the equilibrium position, a uniform and stable magnetic field is formed around the float. A magnetic sensor is installed on the outside of the tapered tube, so that the linear displacement of the float in the measuring tube can be transmitted to the indicator in a non-contact form. After detection and processing, it is finally displayed on the indicator dial or output corresponding standard 4~20mA current signal.

In the vertical conical measuring tube, there is a measuring part that can move up and down - the float (Figure 1). Move up. When the fluid flow increases, the displacement of the float increases; on the contrary, when the fluid flow decreases, the displacement of the float decreases. That is to say, the size of the fluid flow determines the position of the float in the measuring tube, thereby determining the size of the annular area between the float and the conical tube. When the flow rate of the fluid is maintained at a constant flow rate Q, the float is also in a state of dynamic equilibrium and stays at a position h in the conical tube. At this time, the annular area between the float and the conical tube remains constant. The float is acted on by three forces: the gravity G of the float, the buoyancy F received by the float, and the force P of the fluid on the float, and these three forces are in equilibrium. According to the Bernin equation of fluid dynamics, the principle of force balance and the law of fluid continuity, the instantaneous fluid flow through the annular area can be calculated at this time. Therefore, the metal tube rotameter uses a variable area to measure the flow. principle.

Inside the float, a high-performance permanent magnet is embedded. When the float is in the equilibrium position, a uniform and stable magnetic field is formed around the float. A magnetic sensor is installed on the outside of the tapered tube, so that the linear displacement of the float in the measuring tube can be transmitted to the indicator in a non-contact form. After detection and processing, it is finally displayed on the indicator dial or output corresponding standard 4~20mA current signal.