UHZ-DF anti-corrosion magnetic float level transmitter

UHZ-DF anti-corrosion magnetic float level transmitter

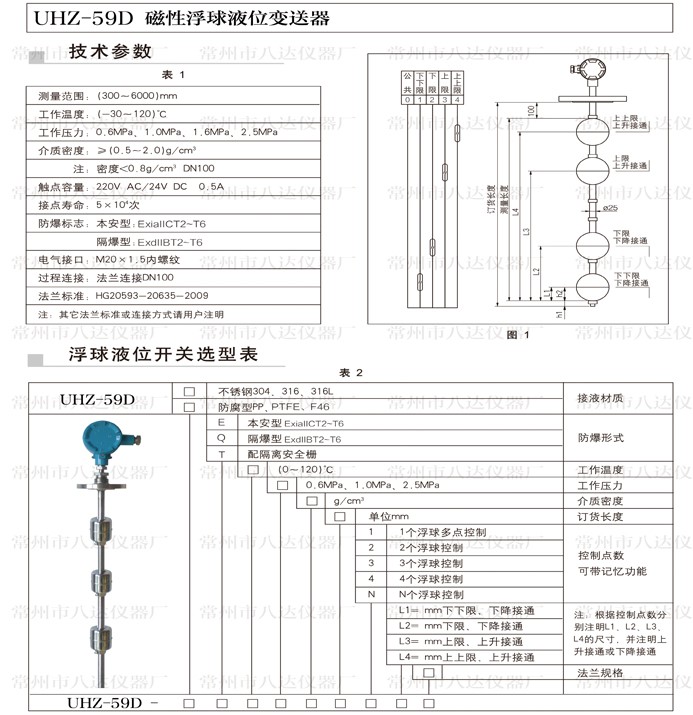

Product descriptionUHZ-59D F top-mounted magnetic floating ball liquid level transmitter series products can achieve

Product Details

Product description

UHZ-59D F top-mounted magnetic floating ball liquid level transmitter series products can achieve high sealing, anti-leakage and safe and reliable liquid level measurement under high temperature, high pressure, high viscosity and strong corrosive conditions, and no blind spot in the whole process measurement , The display is eye-catching, the reading is intuitive, and the measurement range is large. With the liquid level alarm and control switch, the upper and lower limit alarms of the liquid level or boundary level can be realized. The bit signal is converted into a two-wire 4~20mA, 24V.DC standard signal, which realizes long-distance detection, indication, recording and control. The series of products are widely used in petroleum, chemical, electric power, medicine, environmental protection, metallurgy, water treatment and other industries.

Structural Principles

The liquid level transmitter works according to the principle of buoyancy and magnetic coupling. When the magnetic float moves up and down with the liquid level, the action of the magnetic field in the reed switch float corresponding to the liquid level position pulls in, and the resistance value of the resistance chain changes, which is converted into a 4-20Ma standard current signal output by the chip. (with HART protocol according to user needs)

Basic parameters

Measuring range L: 500~8000mm

Measurement accuracy: ±5mm

Working temperature basic type: -20℃-120℃

Working pressure basic type: 1.0-1.6MPa

Media density : 0.8-2.0g/cm3

Flange: DN80 DN100 RF

Flange Standard: HG20592--20635-2009

Other flange standard please specify

Material: Float : 304; 316L; Aluminum; Titanium, PTFE, F46 optional<br Note: UHZ-59D material is 304, 316L, other materials are customized according to user needs.

Measurement accuracy: ±5mm

Working temperature basic type: -20℃-120℃

Working pressure basic type: 1.0-1.6MPa

Media density : 0.8-2.0g/cm3

Flange: DN80 DN100 RF

Flange Standard: HG20592--20635-2009

Other flange standard please specify

Material: Float : 304; 316L; Aluminum; Titanium, PTFE, F46 optional<br Note: UHZ-59D material is 304, 316L, other materials are customized according to user needs.

UHZ-59DF is made of 304+ F46 anti-corrosion magnetic float level transmitter.

For detailed configuration, please refer to the selection table

Install and use

1. First, check whether the data on the liquid level gauge is in line with the order requirements. There must be no magnets and other magnetic substances within 200mm of the liquid level gauge, otherwise it will affect the normal operation of the liquid level gauge.